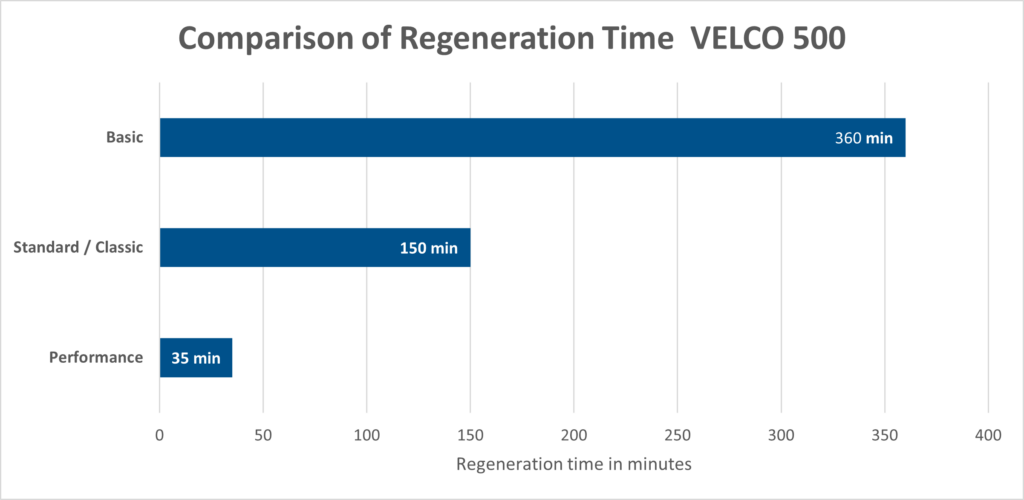

HSR cryopumps can be individually equipped with a wide variety of accessories. An important factor is the regeneration time, i.e., the duration for thawing the pump to ambient temperature. We distinguish four main versions: Basic without regeneration accessories, Classic, Standard, and Performance.

Click here for a comparison of the different versions with respect to regeneration time.

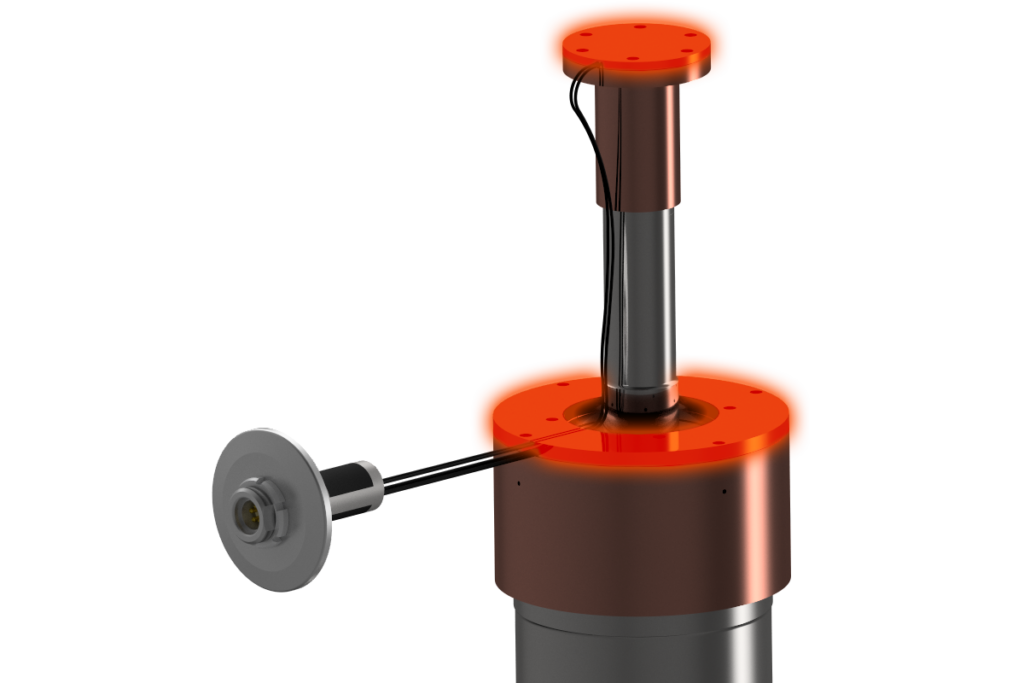

Cold head heating (Performance)

The cold head heater HDL 210 heats the cold head at both temperature stages. This very efficient method enables the shortest regeneration times for time-critical processes. Depending on the application, the partial regeneration function can be utilized.

- 450 W (1st stage) and 70 W (2nd stage) heating power for the shortest regeneration times

- No live parts in contact with vacuum

- DC power supply PUR 250 allows independent control of the two stages

- H-Bus connection from PUR 250 to the HSR controller HCC200/220

- Interlock for temperature-critical applications

Heating cartridge (Standard)

The HSR heating cartridge HCH 201 is a hermetically sealed heater with an integrated PT100. It is the standard solution for assisted regeneration. The mechanical connection with the 1st stage of the cryopump enables short regeneration times.

- Available in DN 25 (125W) and DN 40 (200W) versions.

- Due to encapsulation, operation with corrosive or reactive gases is possible

- Replacement of the heating element and PT100 without disassembling the cryopump is possible in the thawed state

- Power supply via cryo controller CBO 201 or CBR 200 with overheating protection

- With CBR 200 or CBO 050 , possibility of PID control for the 1st stage

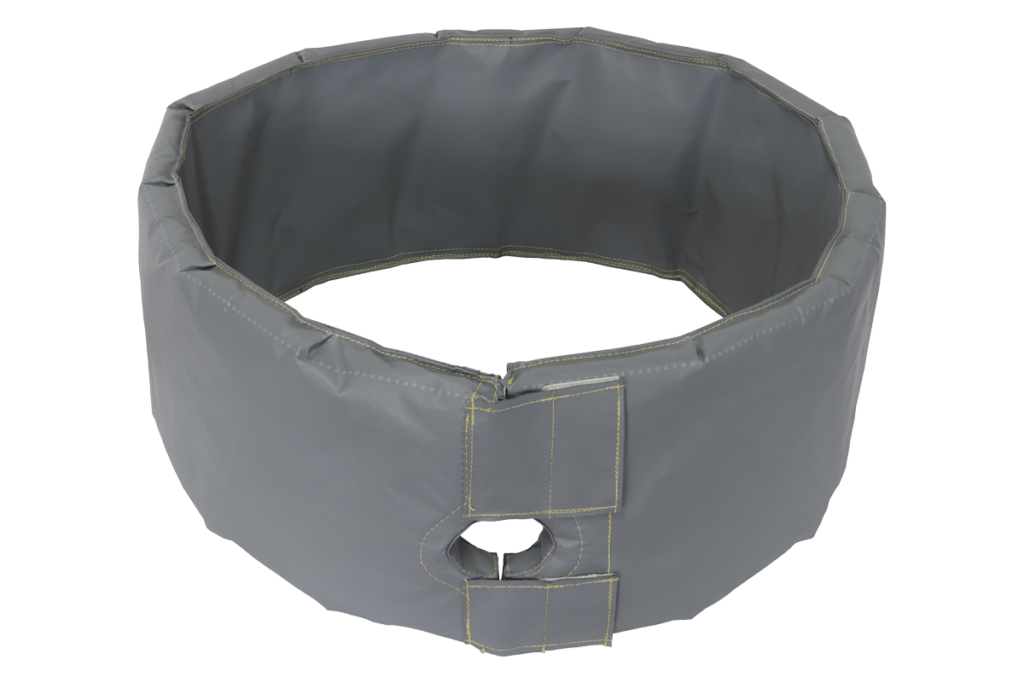

Housing heating (Classic)

Housing heating is the oldest method for assist regeneration of the cryopump. It is exclusively used in conjunction with the purge gas valve. Heat transfer occurs through the introduced gas (nitrogen or dry air). Heating the housing wall also prevents condensation of humidity and the formation of ice on the outer surface

Purge gas valve

The purge gas valve is used for fast regeneration of cryopumps. It is an alternative to regeneration with the heating cartridge. The pressure increase in the pump improves heat convection, and the internal components heat up faster. The released gases are continuously or alternately pumped out by the forevacuum pump.

- Power supply 24 VDC (8W), all common voltages available upon request

- Vacuum-side connection ISO-KF DN 16

- Gas connection compression fitting 1/4″

- Gas connection max. 8 bar

- Seal FKM

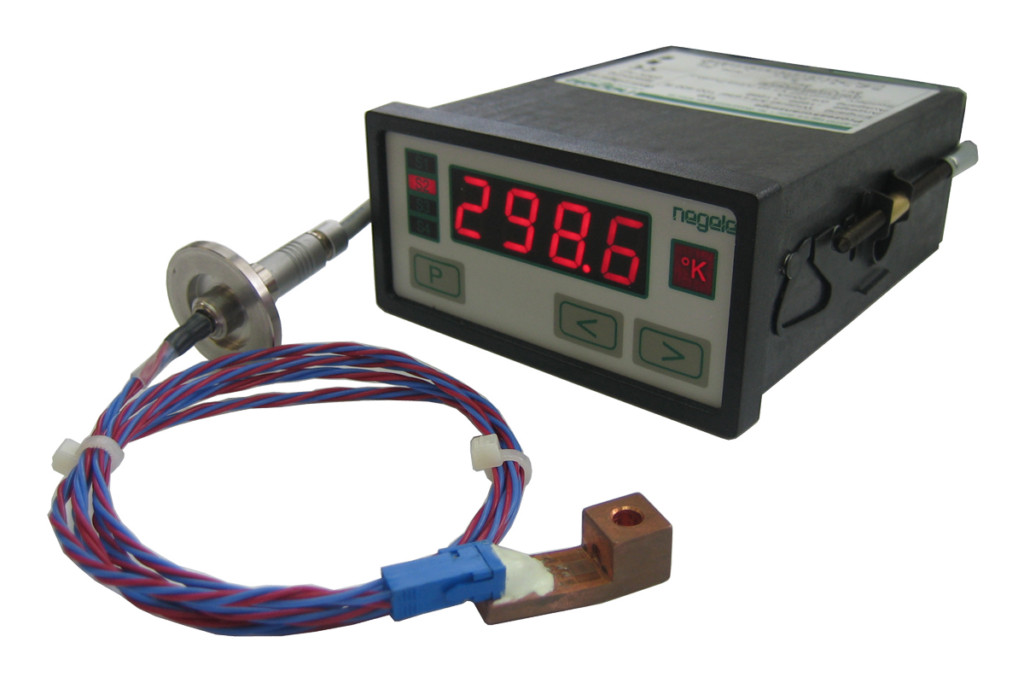

Cryo temperature monitor

In addition to the HCC and HSC controls, HSR offers a simplified temperature measurement system. The HTM display unit can be integrated into any front panel, providing optimal readability. The device is pre-configured for the customer’s application before delivery and is ready for immediate use.

- For all common HSR sensors

- Universal power supply 24-230 V AC/DC

- One or two channel version available

- Two relay contacts with 4-20 mA or 0-10 V outputs

- Adjustable display bars

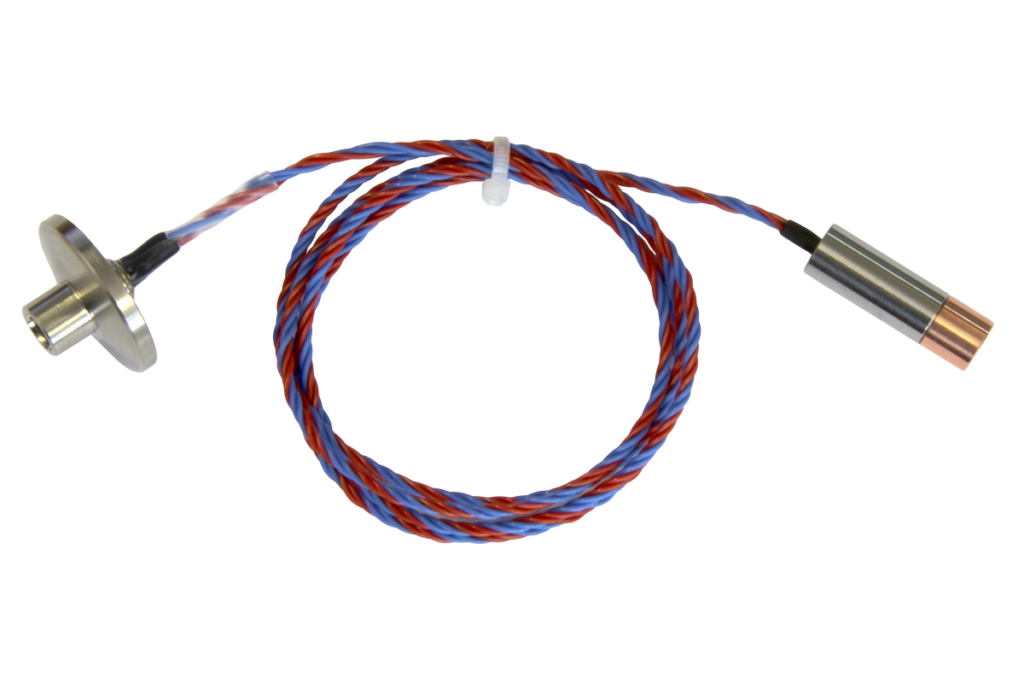

Cryo temperature sensors

HSR has been producing its own sensors for over 20 years. The use of connectors, 4-wire measurement technology, and robust mounting options make the concept universal and unique. The system concept extends from the sensor through the current measurement feedthrough to the measuring electronics.

- KTS: Linearized strain gauge 2 K – 315 K, very good repeatability

- KTP: Platinum-based sensor 25 K – 500 K, very robust and cost-effective

- KTC: Lakeshore CERNOX® sensor 0.1 K – 420 K, excellent in magnetic fields and radiation

- Conductors in vacuum available in PTFE, Kapton®, and PEEK

- Uncalibrated, 2-point calibration, or complete calibration curve available

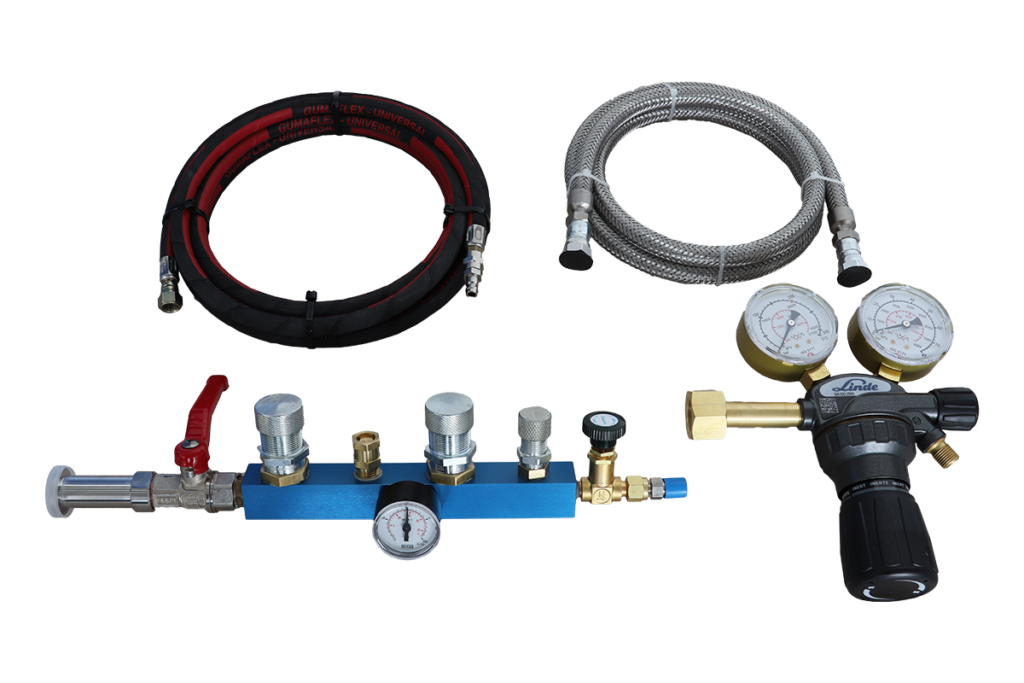

Service adapter set

Adapter block for the maintenance and service of cryopumps: evacuation, venting, and filling cold heads, flexlines, and helium compressors with high-purity helium 4.6 (99.996%).

- Pressure reduction valve

- Connection hose to helium cylinder

- Flexline connection to compressor and cold head

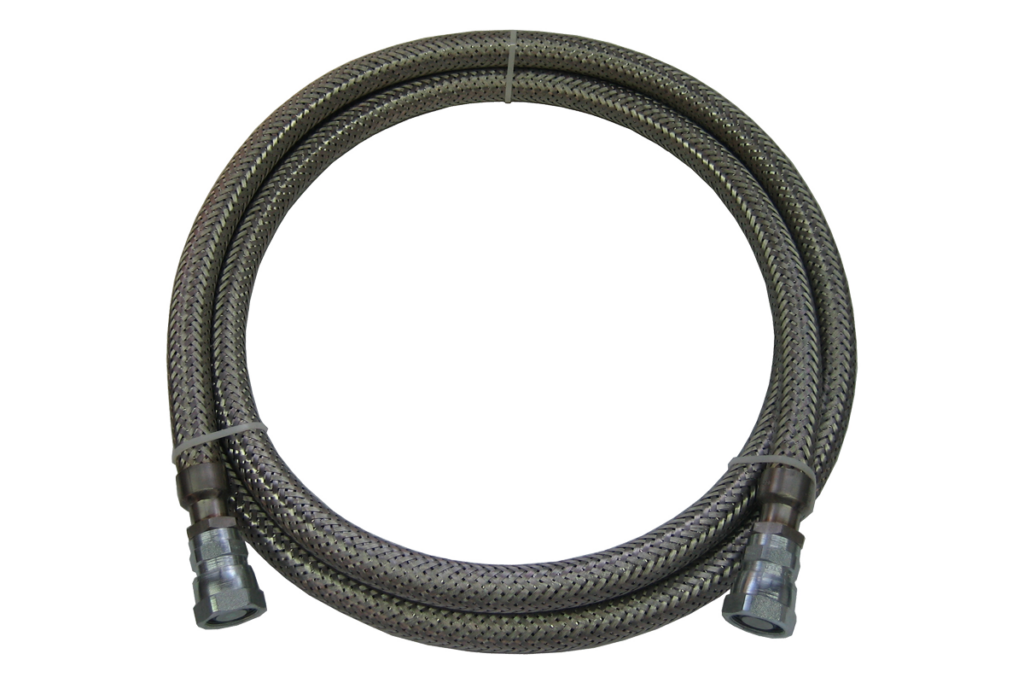

Flexlines

The flexible metal hoses consist of a welded bellows with metal reinforcement. They connect the helium compressor with the cold head in the closed helium circuit.

- Lengths 1.5 to 25 m

- In series connection, over 100 meters possible

- Nominal diameter 16mm for compressor F-70H, nominal diameter 20mm for compressor F-70HP

- Aeroquip® couplings