The angle valves of the HVT series have been developed from the PVA series (plate valves from the former Balzers AG).

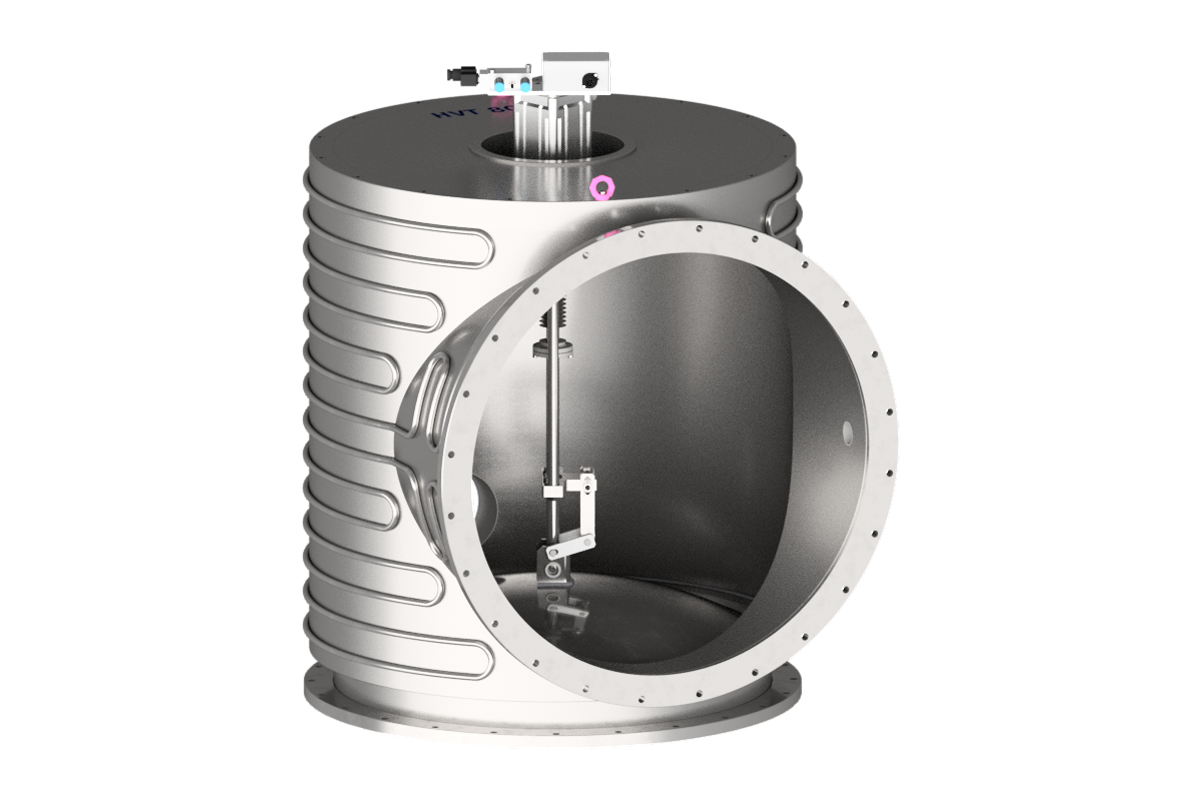

The design is characterized by its patented valve mechanism. Unlike comparable valves, the valve plate is only slightly lifted and then tilted laterally by 90 degrees. This mechanism reduces the required stroke and thus the overall height of the valve while maintaining the maximum conductance.

The actuator rod is sealed against atmospheric pressure with a diaphragm bellows, making it completely free of hydrocarbons and lubricants on the vacuum side. Compared to conventional valves with piston rod actuators, the overall height is at least 30% lower.

The screw connections on the valve plate and housing cover make the bellows and lever mechanism on the vacuum side easily accessible for cleaning purposes. The valve is largely maintenance-free and requires no adjustments after cleaning or revision work.

The housing is available as cooled or uncooled version. When used in conjunction with a diffusion pump, cooled housings additionally minimize the oil flow into the vacuum chamber.

The interior can be coated in black to reduce process heat radiation. This measure decreases the absorbed heat radiation from an attached cryopump, enhancing its suction performance or capacity. The version with the throttling position of the valve plate reduces the conductance of the valve. This allows for higher process pressures than the critical threshold of the vacuum pump, as is the case, for example, if sputtering with argon.

Characteristics

- Size ISO-K DN 320 – DN 1000

- Diaphragm-sealed

- Housing and plate O-ring sealed

- Self-adjusting

- The valve mechanism can be removed without disassembling the valve

- High conductance due to the pivotable plate and the widened valve body

- Compact height due to integrated swivel mechanism

- Electropneumatic actuation

- Easy maintenance

- Stainless steel housing

- Optional throttle position, housing cooling, and black interior coating

- Electric position indication